Welcome to 洛陽賽恩思新材料有限公司

Welcome to 洛陽賽恩思新材料有限公司

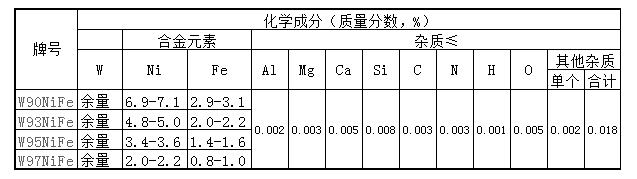

| Brand | Tungsten nominal content | density | hardness | tensile strength | Elongation |

| Weight fraction % | g/cm3 | Rockwell C | MPa | % | |

| Class1 | 90 | 16.95-17.25 | 24-32 | ≥760 | ≥5 |

| Class2 | 93 | 17.45-17.85 | 25-30 | ≥760 | ≥4 |

| Class3 | 95 | 17.95-18.35 | 25-35 | ≥725 | ≥3 |

| Class4 | 97 | 18.45-18.85 | 30-35 | ≥700 | ≥2 |

| Material | Plate | Bar | |

| 90WNiFe | Customizable specifications | Customizable specifications | |

| 93WNiFe | |||

| 95WNiFe | |||

| 97WNiFe | |||

| 90WNiCu | |||

| 93WNiCu | |||

| 95WNiCu | |||

| 97WNiCu | |||